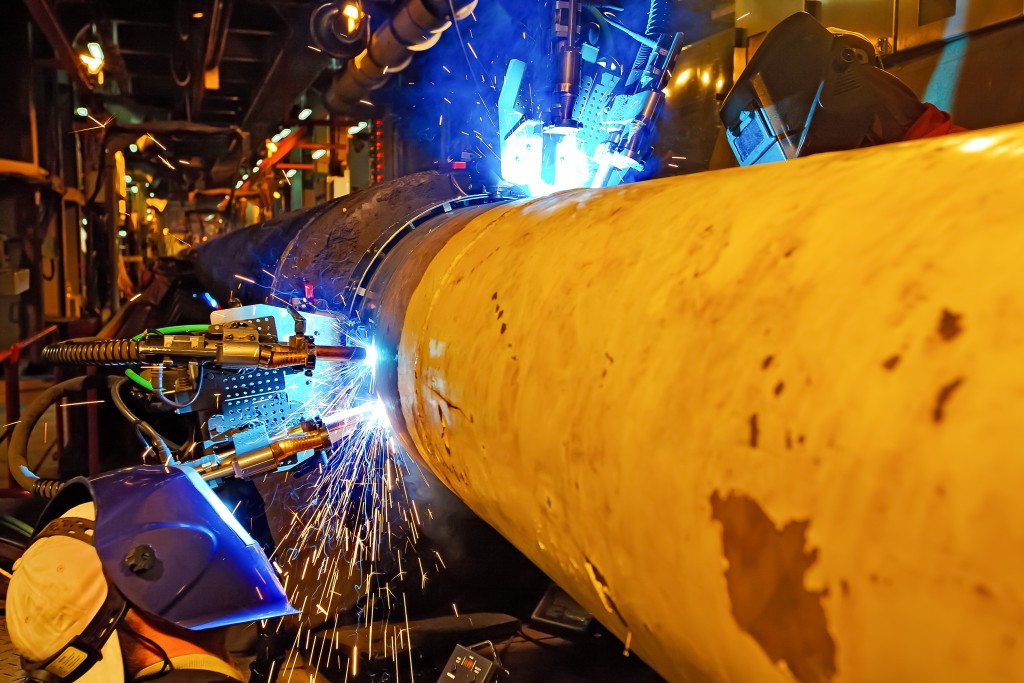

Indeed, not all superheroes wear capes. This statement made more sense during the pandemic than ever. A closer look will tell you that construction workers, as essential workers, played the role to the hilt. So much that even though the numbers of COVID-19 deaths were alarming, they didn’t back down. They continued building. And all thanks to the construction workers, our roofs are secure and our lives are saved.

Unfortunately, construction workers bear the brunt in terms of accidents. For years now (even before the pandemic), construction work tops the chart in terms of total worker deaths. And while hydraulics and big machines play a key role in moving the Earth and tons of load, driving these giants (bulldozers, backhoes, forklifts, and trucks) is one of the major causes of injury in construction.

It’s paramount then that extra caution must be exercised when moving these gentle giants. Hydraulic machines may sound easy to operate but one wrong turn could get ugly pretty fast. Fortunately, there are tried-and-tested ways to manage all that risk. Check out the essentials below.

Be Conscious of Your Surroundings

Case in point: A crane construction incident in 2010. The construction worker was on an I-beam when another I-beam that was lowered by a crane hit him. Apparently, the hydraulic driver was not aware of the other worker.

In this case, you need to put your radar up. Be aware of the things happening in your area before you get your hydraulic machine to work.

For starters, check out if there is falling debris or any electrical work.

When working with electrical lines make sure they are disconnected for the time being. You want to avoid damaging the electricity lines of neighboring houses. Or worse, be electrocuted.

When doing a major digging, for instance, having main utilities switched off is wise. To achieve this you can simply call on the local utility company ahead of time.

The goal is to ensure that everyone around you is safe. And that you are also safe. So look out for workers, passers-by, and yourself.

Proper Equipment Training

It’s true. There are many possible causes of accidents on a construction site. Chief among these are the fatal four with falls having the highest incidence.

But if you dig deeper, you’ll see improper use of equipment stands out as a major cause of the accident. In this regard, making use of equipment you’re not trained to use is waiting for disaster to blow up in your face.

This is even more pronounced with hydraulic giants. As incidents are not as widespread, people might think driving them is manageable. But lack of training can have dire consequences. It can smear your reputation as a contractor. The key to solving this is regular training by qualified industry-certified trainers.

Vehicle entry and exit are also very important. These big machines shouldn’t be used haphazardly. When you enter the cockpit, ensure everything is in the right position. After use, make sure you have turned off the machine and everything switch is in place.

Regular Inspections

One other thing to pay attention to is inspecting machines and equipment. Many people have gotten into construction accidents because they didn’t do the standard inspection before using it. If something is wrong it could lead to a big accident.

Check simple things like oil level and hydraulic fluid. Other parts of the machine important for functioning should be checked as well. If on inspection you find out something is not right then you should call an expert.

In this regard, you should consider getting fresh parts if your machine is defective. While OEM is a good choice, putting your faith in reliable aftermarket construction equipment parts has its own advantages. Far too often, these aftermarket equipment parts are way cheaper and yet still offer top-drawer quality. Plus, they’re easily within reach.

Communication is Key

When working on-site there should be a standard way of communicating. Over the years, spotter signals have been very helpful in preventing accidents. With the signals, your fellow workers know what you are up to. A spotter will be required to wear a bright PPE. That way people can easily see them. ;

Better still, you can opt for two-way radio and just simply communicate. This way there wouldn’t be a misinterpretation of the signal. And you can pass across the information in a more detailed manner.

Observe Limits

Last but not the least, know your limits as a construction worker. As much as you want to get so much done, you shouldn’t forget certain things. For example, never overwork your equipment. It’s counterintuitive. When you do, they can break down. And down the drain, your precious dollars go.

It’s a lot of work. But if you do things right, handling construction hydraulics can be a walk in the park.